In a busy UK-based facility specialising in the preparation, packaging, and distribution of fresh-cut fruit and food products, air quality is more than a comfort—it’s a regulatory requirement. The client operates a high-capacity food production site running 24 hours a day, seven days a week. Due to the nature of food preparation, the environment is strictly regulated and demands constant monitoring to prevent contamination and ensure workplace safety.

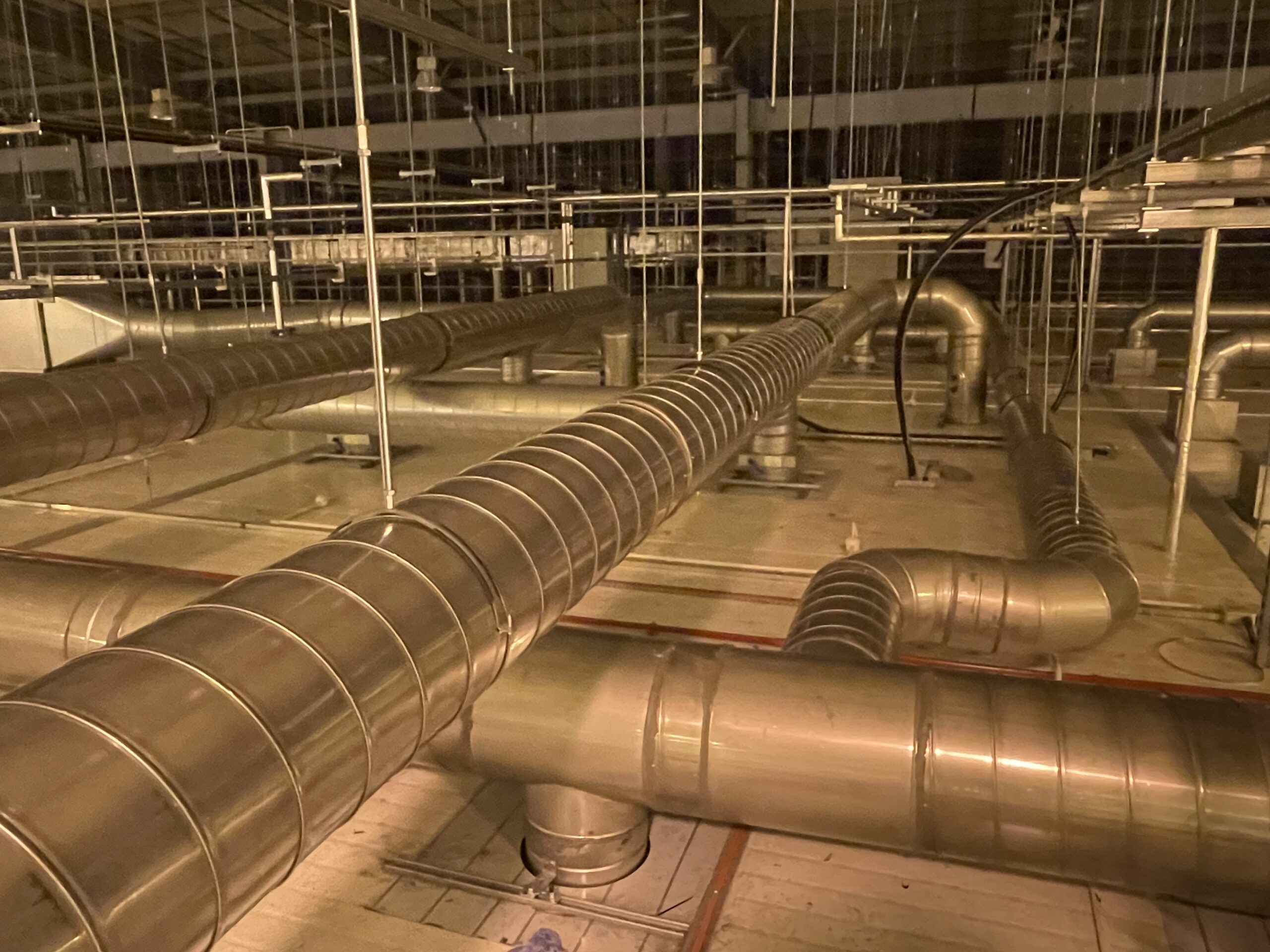

The facility relied on an extensive extraction system to remove fermentation odours created during fruit preparation, alongside a complex air circulation system designed to deliver clean, fresh air into various food processing zones. As these systems ran continuously, they became heavily soiled over time. The build-up of dust and organic matter within the ductwork posed a risk not only to hygiene compliance but also to staff welfare, air quality, and overall operational efficiency.

These air systems were critical to the production line but had not received the level of specialised maintenance they required. With such constant usage, the facility was reaching a tipping point—where performance failure, reduced efficiency, or health-related risks could no longer be ignored.

Upon inspection, a visible accumulation of dust, grime, and biological matter was found at both the extraction and expulsion points of the ductwork. In this type of environment, contamination control is vital, and the system’s state posed both health and reputational risks. The ductwork required urgent specialist cleaning.

Compounding the problem was the strict legal framework that governs commercial ductwork cleaning in the UK. The facility had to remain compliant with the Health & Safety at Work Act 1974, Occupiers Liability Act 1984, BS EN15780 Standard, and EC Regulation 852/2004, all of which place responsibility on the business to maintain a safe and healthy working environment—including the quality of the air staff breathe.

Several critical factors contributed to the condition of the ductwork system. The primary issue was accessibility. Many of the contaminated areas were located within external roof spaces, internal roof voids, and high-level zones directly above sterile food production lines.

These were not simple, open spaces that allowed easy access. They were confined, temperature-controlled, hygiene-sensitive environments, where unauthorised disturbance could jeopardise food safety and halt production.

To address this, ACC Commercial Cleaning Ltd deployed a trained, specialist team equipped with MEWPs (Mobile Elevated Work Platforms) and personal protective equipment suited to high-risk, food-preparation areas. The team worked within narrow hygiene time windows to ensure compliance without disrupting the client’s 24/7 production schedule.

A poorly maintained ductwork system does more than reduce air quality—it compromises every aspect of a food production business. Dirty air ducts can harbour airborne bacteria, fungi, and contaminants, spreading them across sterile zones and posing significant health risks to employees.

If left unresolved, the risks would include:

- Staff illnesses related to poor air quality

- Contaminated food batches requiring disposal

- Production slowdowns or shutdowns

- Failed health and safety audits

- Potential prosecution under UK legislation

In this case, even minor delays in intervention could have led to major loss in productivity, damaged client relationships, and non-compliance fines. Furthermore, cleaning up oil spills and managing contaminated floor areas beneath vents became more frequent due to oil residue from mechanical processes seeping into walkways.

Beyond the immediate health and safety concerns, there were long-term business implications. Any continued failure to maintain the system would have compromised employee wellbeing, invited legal scrutiny, and disrupted client confidence in product quality and safety. There was also a growing risk of increased costs associated with emergency deep cleaning, cleaning up oil spills, and equipment replacement.

Had the situation persisted, the company risked losing its industry certifications and eligibility to supply certain retail clients that demand stringent hygiene documentation.

ACC Commercial Cleaning Ltd created a bespoke hygiene programme tailored to the unique challenges of the site. This included:

- A pre-clean assessment and risk evaluation

- Deployment of a trained, specialist team of hygiene operatives

- Careful scheduling during low-risk hygiene windows

- Use of MEWPs for high-level access and confined space protocols

- Protection of all surrounding production areas to prevent cross-contamination

- Dedicated resources for industrial floor cleaning to manage falling debris and residues during duct access

- Inclusion of cleaning up oil spills from surfaces affected by equipment lubricants

This plan allowed the team to access roof voids, sterilised production lines, and exterior duct systems while ensuring zero disruption to food processing operations.

The client received a full-service solution that not only restored ductwork hygiene but also reinforced compliance through comprehensive documentation.

Key outcomes included:

- All ductwork cleaned to the highest hygiene and safety standards

- Full photographic pre- and post-clean records

- Airflow testing before and after service

- Laboratory analysis for bacteria and fungi levels

- Air quality reporting for employee safety and regulatory purposes

- Targeted industrial floor cleaning throughout the process

- Scheduled cleaning up oil spills on affected walkways and around plant areas

- Zero operational downtime during the works

These outcomes provided assurance that the air quality within the food preparation environment had been restored and that the client’s business could move forward confidently.

Furthermore, a new long-term inspection and maintenance regime was put in place by ACC Commercial Cleaning Ltd. This includes routine duct inspections, ongoing industrial floor cleaning, and rapid-response callouts for cleaning up oil spills that could pose slip hazards or contaminate critical areas.

The result is a safer, cleaner, and more compliant environment, where systems now operate more efficiently and production is protected against risk.

ACC Commercial Cleaning Ltd continues to support the client with expert duct and facility hygiene services, reinforcing the value of regular maintenance in highly regulated industries. From routine industrial floor cleaning to the prompt cleaning up of oil spills, the partnership ensures the client’s reputation and operations remain spotless.