Efficiency and safety – important aspects of cleaning.

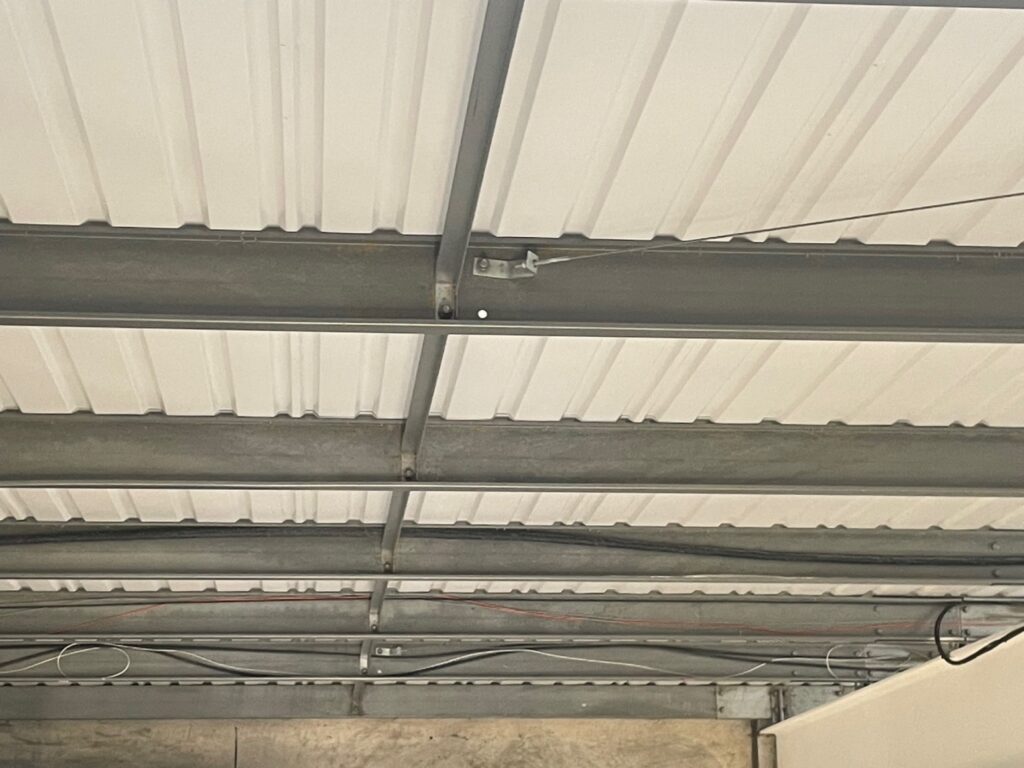

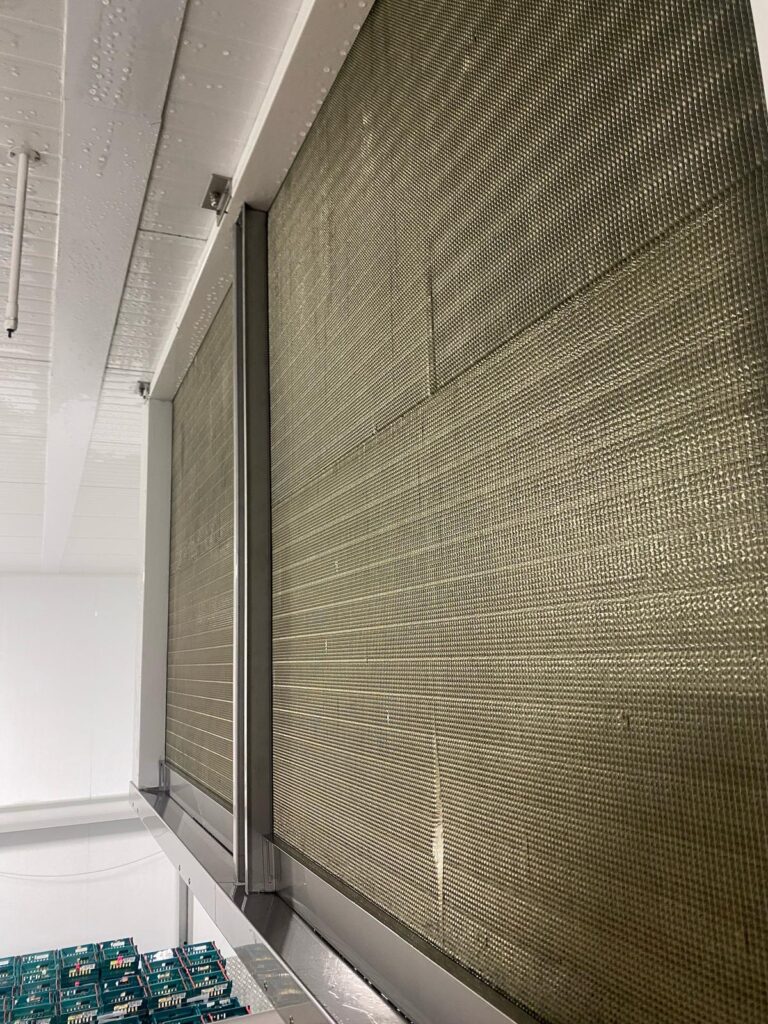

In the dynamic landscape of warehouse operations, maintaining cleanliness is not merely about aesthetics—it is integral to safety, compliance, and efficiency. Particularly, Internal High-Level Cleaning of Warehouses addresses the often-overlooked areas such as ceilings, rafters, ductwork, and lighting fixtures. Neglecting these zones can lead to the accumulation of dust, debris, and contaminants, posing significant risks to both personnel and products.

Warehouses are bustling environments where activities generate airborne particles that settle on high surfaces over time. Without regular cleaning, these accumulations can compromise air quality, leading to respiratory issues among staff. They can increase fire hazards due to combustible dust, affect the performance of equipment like HVAC systems and lighting, and even lead to contamination, especially in food and pharmaceutical storage. A study by GCC Facilities Management revealed that 94% of workers feel more productive in a clean work environment, with 77% believing they produce higher quality work under such conditions. This underscores the critical link between cleanliness and workforce effectiveness.

In the UK, maintaining clean working environments is not optional—it is mandated by law. Several regulations outline employer responsibilities, such as the Health and Safety at Work etc. Act 1974, which obliges employers to ensure, so far as is reasonably practicable, the health, safety, and welfare of all employees. The Workplace (Health, Safety and Welfare) Regulations 1992 specifically state that every workplace and its furnishings must be kept sufficiently clean. Surfaces of floors, walls, and ceilings must be maintained in a condition that allows them to be kept clean. Additionally, the Control of Substances Hazardous to Health (COSHH) Regulations requires employers to manage risks associated with dust and other airborne hazards.

Failure to comply with these regulations can result in significant fines, legal repercussions, and damage to reputation. Beyond compliance, there are considerable operational advantages to maintaining a regular schedule of Internal High Level Cleaning of Warehouses. These include enhanced safety through reduced fire risk, improved air quality resulting in fewer health complaints and absences, and more efficient equipment performance, leading to energy savings and reduced maintenance costs. Businesses also enjoy smoother audits and inspections, particularly in sectors with strict regulatory oversight such as food, pharmaceuticals, and logistics.

Implementing a structured cleaning strategy involves several key actions. A comprehensive assessment of the site helps identify areas most at risk from dust and debris build-up. Planning a cleaning schedule that aligns with warehouse operations ensures minimal disruption to productivity. The use of appropriate equipment, such as MEWPs (Mobile Elevating Work Platforms), and the employment of fully trained and certified personnel guarantees both safety and thoroughness in execution. Documentation of each clean supports compliance and provides traceability in the event of an audit.

Professional cleaning partners who specialise in Internal High Level Cleaning of Warehouses offer unmatched advantages. Their teams are trained in working at height, using specialist access equipment, and applying cleaning techniques suited to industrial environments. They also bring an understanding of sector-specific requirements and can tailor their services accordingly. For businesses looking to protect their investment and ensure long-term operational integrity, partnering with experienced professionals is a wise decision.

- Improves indoor air quality and creates a healthier working environment

- Helps ensure compliance with COSHH and Health & Safety regulations

- Reduces fire risks from built-up dust on high surfaces

- Prevents machinery and lighting inefficiencies caused by grime

- Minimises contamination risks in food and pharma warehouses

- Enhances staff wellbeing and productivity

- Extends the lifespan of HVAC systems and other infrastructure

- Assists in successful audit outcomes and quality checks

- Helps protect stored goods from airborne particles

- Creates a more professional and well-maintained facility appearance

The reality is that Internal High Level Cleaning of Warehouses is often neglected until problems arise, yet it should be an integral part of any facility management plan. High-level areas are typically out of sight, but they can become hotbeds for dust accumulation, particularly in facilities with constant movement, open doors, or exposed racking systems. The consequences of inaction are not only financial—ranging from equipment damage and insurance claims to legal penalties—but also reputational, particularly for businesses that supply large retailers or work within regulated industries.

Regular cleaning also helps extend warranties on key equipment and infrastructure. Many manufacturers include clauses that void warranties if equipment is shown to have failed due to lack of maintenance or build-up of foreign materials. This makes Internal High Level Cleaning of Warehouses a cost-saving measure in the long run.

In terms of sustainability, a clean warehouse operates more efficiently, with lower energy usage from systems not weighed down by dirt and dust. Lighting, for instance, becomes far more effective when free from grime, potentially reducing energy costs. Additionally, better indoor air quality reduces the burden on HVAC systems, as advised by The American Society of Mechanical Engineers, again offering environmental and cost benefits.

Ultimately, Internal High Level Cleaning of Warehouses is not a luxury or a periodic fix—it is a crucial, ongoing requirement for any business that values safety, productivity, and professional standards. The phrase may not be glamorous, but the results speak for themselves: healthier staff, protected stock, improved energy efficiency, and peace of mind knowing that your business is operating in compliance with the law and best practice guidelines.

For facilities managers, health and safety officers, and business owners alike, this form of preventative maintenance is a clear-cut decision. Partnering with a trusted and experienced cleaning provider ensures that every corner of your warehouse—from floor to ceiling—is contributing positively to your operation. Don’t wait until your next audit or breakdown. Incorporate a routine of Internal High Level Cleaning of Warehouses into your facility plan today, and safeguard your operation from the hidden dangers above and contact ACC Commercial Cleaning Ltd.